ENGINEERING TECHNOLOGY

RESEARCH CENTER

What is a Surface Finish?

A surface finish may be defined as a “coating” located at the outermost layer of a PCB

(which is dissolved into the solder paste upon reflow or wave soldering) (which is dissolved into the solder paste upon reflow or wave soldering)

Note:

(Base) Metal Plating is typically copper (in most cases).

But, in a few (like ENIG) the Nickel-phosphorous(5-12% P co-deposit) serves as the solderable surface.

Why use a Surface Finish?

The surface finish protects the PCB

Surface Copper until it’s Assembled

How to Select a Proper Surface Finish?

Reasons for Finishes Reasons for Finishes

• Coplanarity (See Below)

• Lead-Free (RoHS and WEEE) (RoHS 5 or RoHS 6)

• Contact Resistance (Compression Connection)

• Tarnish Resistance

• Press-fit Requirements

• Wear Resistance

• Hardness

• Chemical Resistance Chemical Resistance

• Wire Bonding (Au or Al?)

• Cost

• Compatibility with other Surface Finish

surface_finish_new_2011.pdf

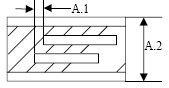

| Process | Description | Tolerance | Figures(mm) | |

| A.Lamination | 1.Multi-layer alignment precision | ±3mil | ||

|

||||

| 2.Minimum laminated board thickness | 0.4MM | |||

| 3.Board thickness tolerance | <1.0以下±0.1MM,1.0以上±10% | |||

| B.Basic Material | 1.Material | FR-4,铝基,高频板材,聚四氟已烯,厚铜箔,纸板,BT板材,PI板材,Rogers4003,pp4403, | ||

| 2.Thickness capability | 最小0.2MM,最大6.0 | |||

| 3.Thickness capability(HAL) | 最小0.6MM,最大3.0mm | |||

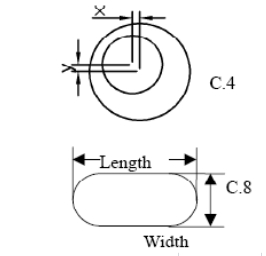

| C.Drilling | 1.Maximun drill size | 6.5mm | ||

| 2.Minmum drill size | 0.2mm | |||

|

||||

| 3.Hole size tolerance | ±3mil | |||

| 4.true position tolerance | ±3mil | |||

| 5.Slot true position tolerance | 孔径〈10MM以下:公差±0.2MM,孔径≥10以上:公差±0.2MM | |||

| 6.Slot width tolerance | 孔径〈10MM以下:公差±0.2MM,孔径≥10以上:公差±0.2MM | |||

| 7.Slot length tolerance | 孔径〈10MM以下:公差±0.2MM,孔径≥10以上:公差±0.2MM | |||

| 8.Slot length to width ratio | 2:01 | |||

| 9.Aspect Ratio | ||||

TECHNICAL CAPBILITY

surface_finish_new_2011.pdf